Description

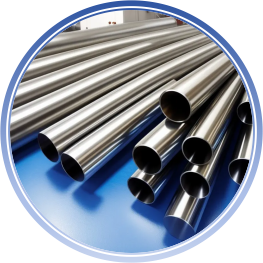

Product Introduction

Electrochemical polishing stainless steel tube is a high-quality stainless steel pipe material. This pipe is made of high-quality stainless steel and has good corrosion resistance and strength. The surface of the EP pipe is electrolytically polished, giving it excellent corrosion resistance, high inner surface smoothness, and cleanliness, enabling it to maintain good performance even in harsh environments such as high temperatures and high pressures.

Application

Commonly used in semiconductors, LCD panels, biomedicine, aerospace, scientific research experiments, and high-end manufacturing.

Product Material

304, 304L, 316, 316L Hastelloy, nickel-based alloys, and other special stainless steel materials.

Standards

GB、EN、ASTM、GOST、DIN、JIS , etc .

Grades

304/304L(ASTM A312 TP304)、316/316L(ASTM A312 TP316)、321(ASTM A312 TP321)、310S(ASTM A312 TP310S)、UNS S32205、904L超级奥氏体(UNS N08904)、254SMO(UNS S31254)

Certification Standards

ASTM A269(Seamless Pipe)、ASTM A270(Sanitary Pipe)、EN 10217-7(EN standard pressure pipe)

Contact Us