Description

Product Description

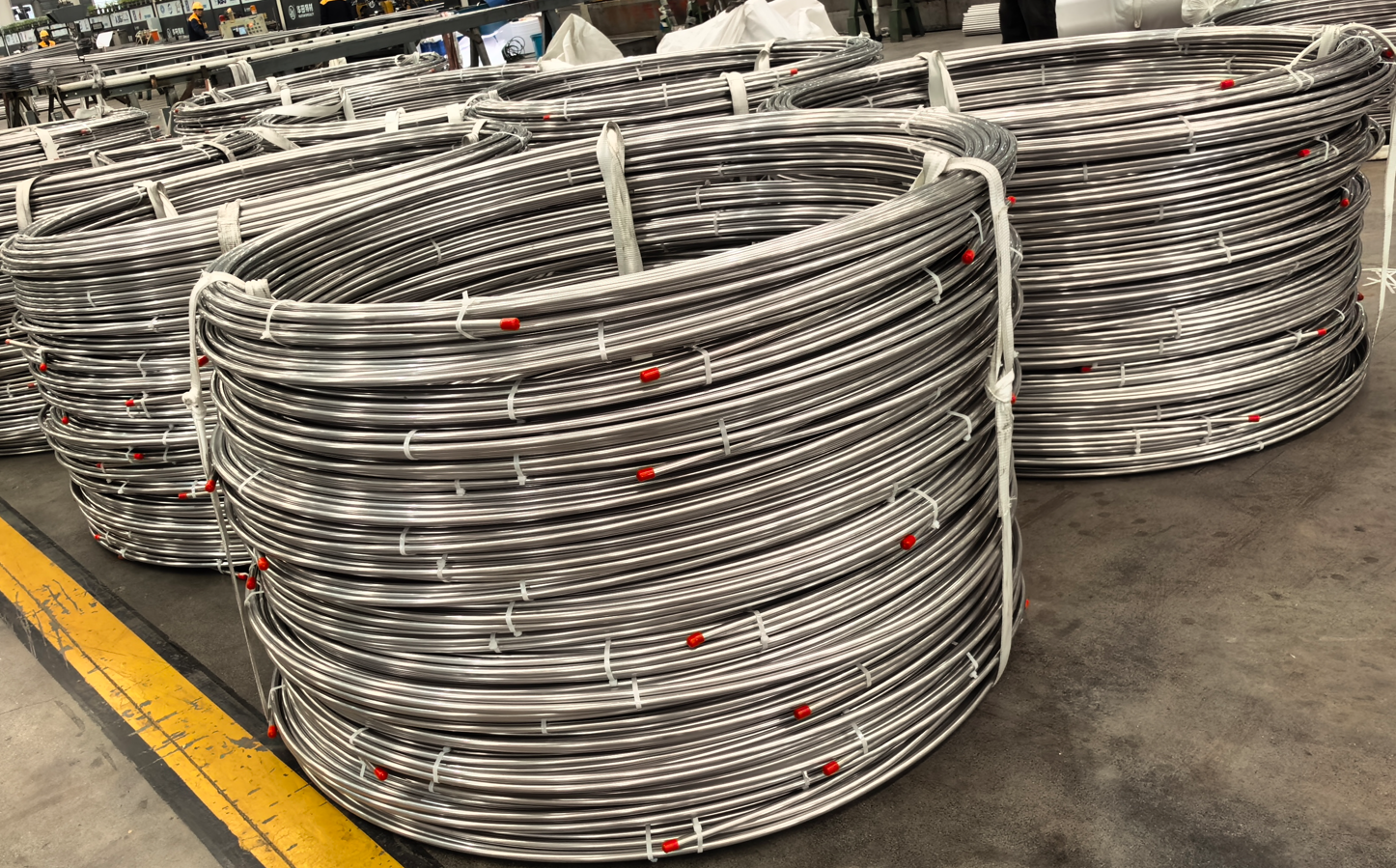

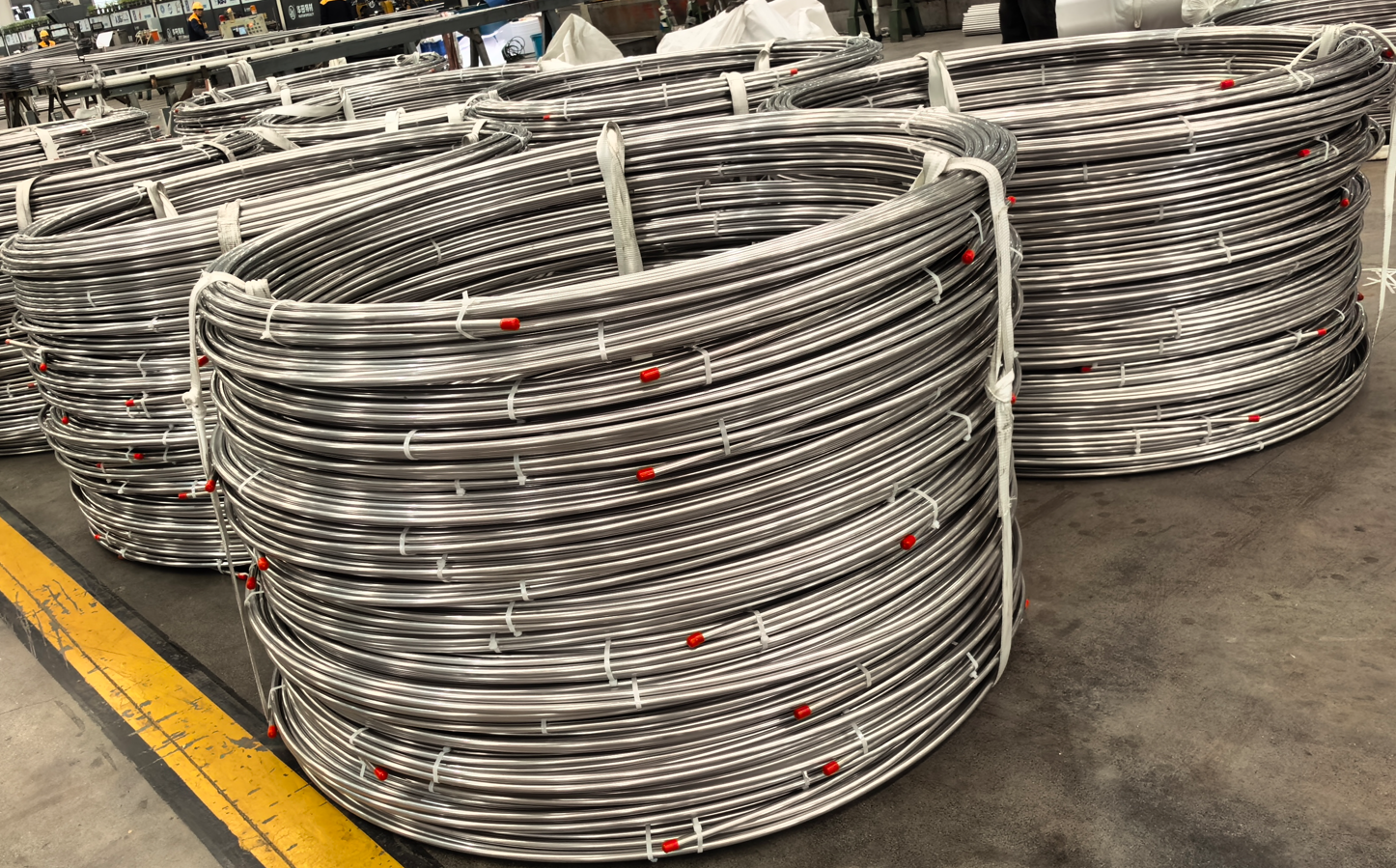

Coiled tubing is a tubular device formed by spirally bending a cylindrical surface, primarily used as a component for fluid heat exchange or energy transfer. In industrial applications, they primarily serve as the core components of spiral-wound heat exchangers. Utilizing advanced cold-drawing technology from South Korea and Japan, the dimensional tolerances of the steel tubes are controlled with greater precision. Additionally, an advanced bright annealing gas-protected process ensures that the steel tube surfaces do not come into contact with oxygen, preventing the formation of oxide scale. This results in cleaner, brighter, and smoother tube surfaces.

Product advantages

No need to connect fittings, saving installation procedures, greatly reducing installation time and lowering installation costs. At the same time, the use of coils can reduce the risk of leakage from pipe fittings and improve the performance of the piping system.

Application

Widely used in the manufacture of various containers, furnace shells, furnace plates, bridges, and automotive structural steel plates, low-alloy steel plates, bridge steel plates, shipbuilding steel plates, boiler steel plates, pressure vessel steel plates, patterned steel plates, and automotive chassis steel plates. Certain parts of tractors and welded components.

Standards

ASTM、ASME、EN、GB、JIS、DIN、GOST.etc

Grades

304、304L、316、316L、321H、316Ti、347、347H.etc

thickness

0.05-1.0mm

Width

10-650mm

(100-meter ultra-long seamless coil)

Contact Us